Product development is incomplete without prototyping. It is a place for design teams to test new concepts by building a prototype.

What is Rapid prototyping?

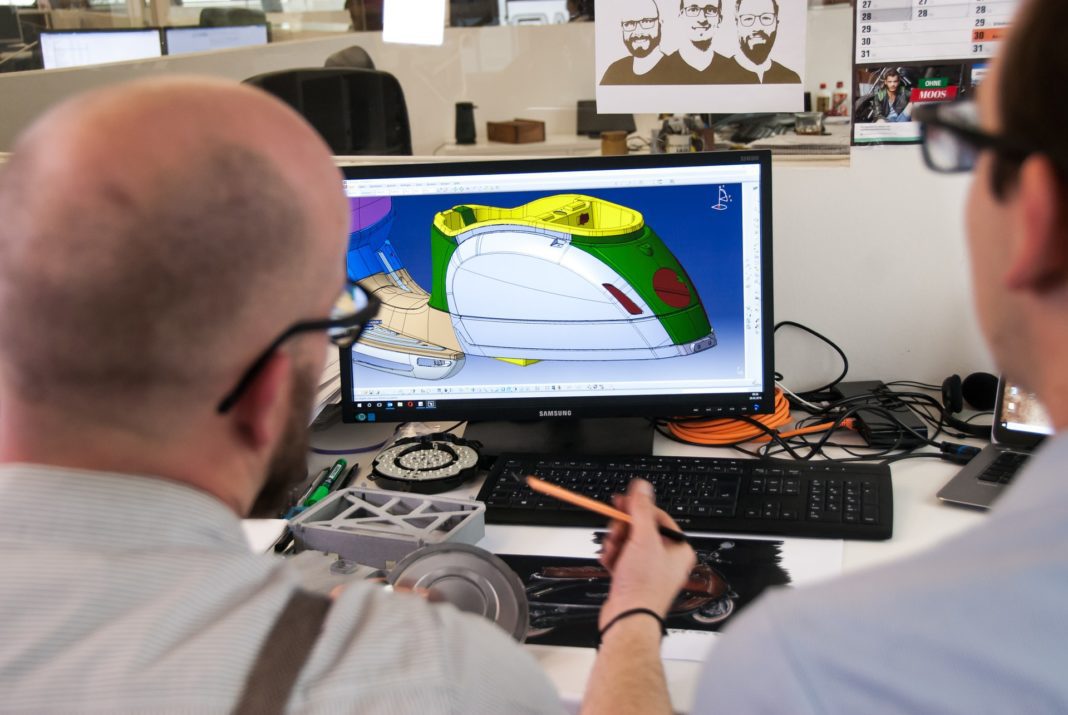

Rapid prototyping (RP) uses a variety of manufacturing processes to generate an actual product from CAD model data rapidly. There are no limits to the usage of rapid prototyping at any point of the product development cycle for any component or sub-component. Many iterations of fresh product design may be made utilizing test data to attain desired parts via prototyping.

As a relatively new concept rapid prototyping services may be defined as the quick creation of a prototype to aesthetically and functionally assess a component or aspects thereof. Manufacturers can test prototype products by assembling individual elements in a short period.

A prototype assesses the design, tests the technology, analyzes the operating principle, and offers final product requirements in an engineering product design environment. The method of engineering products and, more crucially, creating new products both need prototypes.

3D printing and rapid prototyping

- What is the difference between rapid prototyping and 3D printing?

3D printing and additive manufacturing are more often used in product development to produce prototypes swiftly. You cannot underestimate the benefits of 3D printing. However, due to rising production prices, specific prototypes may not afford to use the seven additive manufacturing technologies, despite their advancements.

What is the significance of rapid prototyping?

To stay competitive in today’s fast-paced consumer market, companies must quickly create and launch new items. Rapid prototyping is the essential component of new product development since it allows for speedier product development and technological innovation, both crucial to business success. It’s one of the reasons why the rapid prototyping market size is worth so much. Rapid prototyping aims to do the following.

- Rapid prototyping is crucial for generating successful goods since it speeds up developing new items.

- Validation of the design’s shape, fit, and functionality at an early point in the design process

- Verification of the final product against the technical specification and the commercial goals

- It enables testing of the concept’s goals and finalizing the product specification.

- An end-user, client, customer, or other stakeholders may have a firsthand look at the prototype and provide comments.

Types of Rapid prototyping

- Stereolithography (SLA)

SLA was the first commercially viable 3D printing process to be developed using SLA technology. It is a cost-effective and time-saving method of rapid prototyping. Prototypes are built layer by layer using solidified photosensitive liquid. A computer-generated UV light is typically used to harden the liquid.

- Selective Laser Sintering (SLS)

Plastic and metal prototypes may benefit from SLS. Prototypes are built layer by layer with the assistance of a powder bed, which you heat with a laser and then cool. However, prototype components are a lot weaker than those made via stereolithography. The surface might be a little rough when done with the final product.

- Fused Deposition Modelling (FDM)

FDM is a less costly and easier-to-understand procedure than traditional manufacturing methods. You can find it in most non-industrial 3D computers. A melted spool of thermoplastic filament is overlaid with a liquid to make a three-dimensional object. When 3D printing was in its infancy, FDM was used, which resulted in shaky designs. However, it will be more suited for product development as it evolves.

- Binder Jetting

The binder jetting process makes it possible to print many pieces simultaneously. Despite this, the components produced by the SLS are much more durable than those made by this method. This technology is similar to SLS in that it uses a powder bed to build prototypes.

Applications

Product designers use rapid prototyping to produce representative prototype pieces quickly. Visualization, design, and development of the manufacturing process before mass production may be aided by this.

A broad number of sectors, including medical and aerospace, have used rapid prototyping since its inception as a tool for creating components and scale models for the automobile industry.

Another usage for RP is rapid tooling. A component, such as an injection mold plug or an ultrasonic sensor wedge, is created and then utilized as a tool in another process.

An experimental model may be developed more quickly via rapid prototyping. In addition, you will be able to see and feel the prototype design in action.